Introduction

Bone is a dense tissue constituted of minerals and organic components. The repair of a fracture necessitates implants such as plates and nails. These procedures involve drilling into the bone. Drilling produces two forces: a thrust and a cutting force. The thrust force acts in the opposite direction of the drilling and is related to the type of bone drilled. The cortical bone, for example, generates a greater thrust force than the cancellous bone. On the other hand, the drill speed, torque, and diameter of the drill bit all influence the amount of cutting force emitted at the bit's cutting edge.

A wide array of drills ranging from pneumatic to battery-operated drills and even electric drills are utilized in orthopedic surgery. Each drill has its unique set of advantages and disadvantages. Because of its benefits, most trauma surgeons in the developing world prefer the electric drill. The pros include cost-effectiveness, ease of use, and reusability. 1

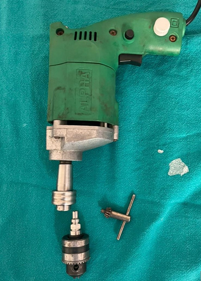

Figure 3

Reaming of tibial canal with flexible reamer and using an electric drill due to cannulation.

Table 1

Comparison of three drills

Technical note

The prototype of the drill used by us is from a local manufacturer—[Figure 1]. The handpiece is wholly made of plastic, while the initial part of the body meant for chuck attachment is made of iron. We replaced the original Jacobson chuck with a stainless steel coupling to hold the reamer for nailing. The initial iron chuck was replaced with a stainless steel chuck. There were three reasons to do that: 1. we had to modify the chuck to fit in the coupling 2. Since the chuck could be detached from the drill, we could autoclave it 3.Steel chuck is corrosion resistant, and with constant exposure to blood and water during surgery, there was a high likelihood that the original iron chuck would corrode and increase the chances of infection. This chuck was equipped with three jaws that securely grasped the drill bit or K wire and opened and closed with a key. The ergonomically built handpiece features a cord for the power supply. We increased the power cable length to seven meters to keep it out of reach of anesthesia equipment and oxygen cylinder. The original drill had a constant speed, so we modified the speed control using a knob to alter the pace depending on whether we used it to drill holes in bone or ream.

To maintain the drill's sterility, we placed the drill in a formalin chamber and autoclaved the detachable chuck. In addition to the above modifications, we made the drill cannulated to allow the guidewire to pass through while reaming. Alternatively, we use EtO (Ethylene Oxide) for sterilization of the drill. The drill is removed from the box and covered with a sterile sheet and bandage [Figure 2]. Following surgery, the sheet is removed, and any blood is cleaned from the surface with alcohol and hydrogen peroxide. We can also use a camera cover used in arthroscopy or a stockinet to cover the drill or make one permanent drill cover with a cloth and autoclave it every time before its use. After complete opening and closing of the jaws, special care is taken to clean the mouthpiece. The entire drill is cleaned with a spirit or alcohol-based compound before reinserting into the formalin chamber. We have successfully used the altered electric drill to perform interlocking nail placement in the tibia and femur of many patients. [Figure 3]

Discussion

While the pneumatic drill system (PDS) and the Orthopedic Battery Drill (OBD) are employed in orthopedic practice, their costs are incredibly high. The pneumatic drill system is equipped with a robust hose, restricting the surgeon's mobility when targeting screws at an angle. The primary advantage of a battery drill is the freedom with which it may be maneuvered in desired directions without using a hose or cable. The downside of battery drills is that the drill's 12V battery must be charged for 25 minutes to 240 minutes before usage. The batteries must be replaced between surgeries, increasing operating time and jeopardizing sterilization. Another issue with the battery drill is that its torque decreases as the battery charge depletes.

An electric drill costs approximately 1500 Indian rupees (20 US Dollars), and the hardware required to modify reaming system costs an additional 2500 Indian rupees (approx 30 US dollars), which may serve as another excellent replacement. Our electric drill with reaming design costs almost a quarter of Bosch battery drills without reaming capability. In contrast, conventional Orthopedic battery drills and pneumatic drill systems cost 150 times. Concerns about sterility, heat necrosis of bone, power cord concerns, and drill maintenance are the most common reservations about using electric drills in orthopedic surgery.

Matthews and Hirsch observed no significant change in temperature when drilling human cadaveric femora at rates ranging from 345 to 2900 revolutions per minute, indicating that overheating was more dependent on the drilling pressure.2 Sharawy proved in a comparable study that raising rotational speed from 1225 to 2500 rpm reduced heat output.3 The bit design, bone tissue resistance, rotational speed, and force produced at the cutting edge of the drill bit contribute to bone heat generation and thermal necrosis.4 While it is widely believed that an electric drill is insufficient for bone use, resulting in splintering/overheating, etc. However, when we evaluated the Bosch battery drill, Stryker system 6, and an electric drill, we discovered they are all comparable in terms of RPM and weight (Table 1).

Because the electric drill is manufactured of plastic and iron, it cannot be autoclaved. Goveia et al. investigated the efficacy of Ethylene Oxide (EtO) in sterilizing electric drills. They confirmed that this process is safe and effective in sanitizing and reusing electric drills.5 We housed our drill in a formalin chamber because Taylor and Barbeito demonstrated formaldehyde gas thoroughly decontaminated laboratory chambers and scientific instruments in 1969. The source of this gas was paraformaldehyde powder. It suppressed both sporicidal and nonsporicidal bacteria and neutralized toxins and viruses. Formaldehyde, often known as formalin, was excellent disinfection for facemasks from the COVID 19 virus by Haro et al. in 202.6 Electric drills can also be autoclaved in a Formalin autoclave at 65 degrees Celsius. Residual formalin is negligible with an autoclave, and sterilization levels are comparable to Ethylene Oxide.7

Following the surgery, the drills' surface is cleaned with alcohol and hydrogen peroxide before placing it in the formalin chamber. We also draped the drill with autoclaved stockinet or drapes to avoid direct contact with blood and water during operation and to enhance protection.8 Alternatively, we can also employ the ready-to-use sterile camera covers to prevent smudging with blood and boost its longevity.

We can not only drill K-wires with the modified electric drill but also ream the medullary canal and tap utilizing the reverse and forward triggers. Among the disadvantages of using an electric drill are the inability to attach the K-wire collet system, the lack of a paired saw system, and, albeit minor, cable concerns. The electric drill has most of the functionality of a premium orthopedic drill for less than 150 times the price. We eliminated a significant disadvantage by cannulating it, making it comparable to Orthopedic Battery drills. As a result, we encourage and advocate for the routine use of electric drills without reservation in most trauma procedures, including nail reaming in countries with limited resources.

Conclusion

The literature contains adequate evidence to refute misconceptions about electric drill overheating and bone thermal necrosis. There are various scientifically validated methods for sterilizing the electric drill effectively. Due to its affordability and ease of maintenance, particularly in poor economies, our inventions such as speed control and drill cannulation make it an all-purpose piece of equipment for most trauma surgeries.